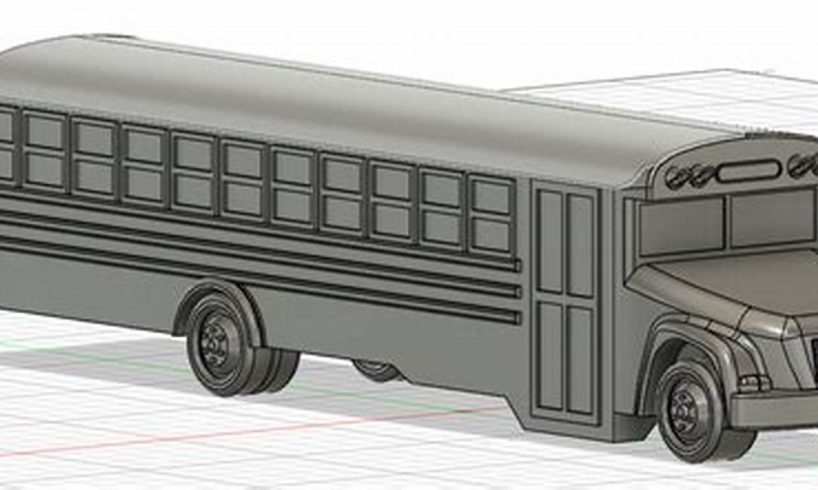

3D printing technology has revolutionized various industries, including the transportation sector. One innovative application of 3D printing is the creation of school buses. 3D-printed school buses offer numerous advantages over traditional buses, making them an attractive option for schools and transportation providers.

The primary benefit of 3D-printed school buses lies in their cost-effectiveness. Traditional school buses are expensive to manufacture, often requiring large production facilities and specialized equipment. In contrast, 3D-printed buses can be produced in smaller, more agile facilities, using less material and labor. This streamlined production process significantly reduces manufacturing costs, making 3D-printed buses a more affordable option for schools with limited budgets.

In addition to cost savings, 3D-printed school buses also offer greater design flexibility. With traditional manufacturing methods, buses are typically limited to a fixed set of designs and configurations. However, 3D printing allows for the creation of customized buses that can be tailored to the specific needs of each school. Schools can choose from a range of options, including different seating arrangements, wheelchair accessibility features, and even unique exterior designs, ensuring that their buses meet the unique requirements of their students and community.

Furthermore, 3D-printed school buses offer improved safety features. Traditional buses are often made of metal, which can be prone to rust and corrosion over time. 3D-printed buses, on the other hand, can be constructed using advanced composite materials that are lighter, more durable, and resistant to corrosion. These materials provide better protection for students in the event of an accident, enhancing their overall safety.

Beyond the benefits mentioned above, 3D-printed school buses also contribute to environmental sustainability. Traditional buses rely on fossil fuels, which contribute to greenhouse gas emissions. 3D-printed buses, on the other hand, can be manufactured using sustainable materials and powered by electric motors, reducing their environmental impact and promoting a cleaner future for transportation.

In conclusion, 3D-printed school buses offer a range of advantages over traditional buses, including cost-effectiveness, design flexibility, improved safety features, and environmental sustainability. As technology continues to advance, 3D-printed buses are expected to become even more sophisticated and widely adopted, transforming the way students are transported to and from school.

1. Cost-effective

The cost-effectiveness of 3D printing is a major advantage in the production of school buses. Traditional manufacturing methods for school buses involve large-scale production lines, extensive labor, and the use of expensive materials. In contrast, 3D printing offers a more agile and cost-efficient approach.

With 3D printing, school buses can be produced in smaller, more flexible facilities. The digital nature of 3D printing eliminates the need for physical molds and tooling, reducing upfront investment costs. Additionally, 3D printing allows for the use of innovative materials that are lighter and more durable, further reducing production expenses.

The cost savings associated with 3D-printed school buses can be significant. A study by the University of California, Berkeley, found that 3D-printed buses could be produced for up to 50% less than traditional buses. These cost savings can be passed on to schools and transportation providers, making 3D-printed school buses a more affordable option.

The cost-effectiveness of 3D-printed school buses has important practical implications. Schools with limited budgets can now consider 3D-printed buses as a viable option. Additionally, 3D printing can enable the production of school buses in remote or underserved areas, where traditional manufacturing facilities may not be feasible.

In conclusion, the cost-effective nature of 3D printing is a key factor in the adoption of 3D-printed school buses. By reducing manufacturing costs, 3D printing makes school buses more affordable and accessible, ultimately benefiting schools, transportation providers, and students.

2. Design flexibility

The design flexibility offered by 3D printing is a major advantage in the production of school buses. Traditional manufacturing methods limit schools to a fixed set of bus designs and configurations. In contrast, 3D printing allows for the creation of customized buses that can be tailored to the specific needs of each school.

- Seating arrangements: Schools can choose from a range of seating arrangements to accommodate different student needs. For example, buses can be designed with extra legroom, wider seats, or specialized seating for students with disabilities.

- Accessibility features: 3D printing enables the integration of accessibility features such as ramps, wheelchair lifts, and handrails. This ensures that students with mobility impairments can safely and comfortably access and use the bus.

- Exterior designs: Schools can customize the exterior design of their buses to reflect their school colors, mascot, or unique identity. This can help foster a sense of school spirit and community.

- Safety features: 3D printing allows for the incorporation of additional safety features, such as reinforced body panels, impact-absorbing materials, and advanced lighting systems. These features can enhance student safety in the event of an accident.

The design flexibility of 3D-printed school buses has important implications. It empowers schools to create buses that are not only functional but also tailored to their unique requirements and values. This can lead to improved student comfort, safety, and overall satisfaction with the school transportation system.

3. Enhanced safety

The use of advanced materials in 3D printing significantly enhances the safety of school buses. Traditional school buses are typically made of metal, which is prone to rust and corrosion over time. In contrast, 3D-printed buses can be constructed using advanced composite materials that are lighter, more durable, and resistant to corrosion.

These advanced materials provide several key benefits for school bus safety:

- Improved durability: Composite materials are more resistant to impact and wear than traditional materials, making 3D-printed buses more durable and long-lasting. This reduces the risk of breakdowns and accidents, ensuring that students are transported safely to and from school.

- Enhanced crashworthiness: Composite materials can absorb more energy in the event of a crash, reducing the risk of serious injuries to students. 3D printing also allows for the creation of complex safety structures that can further enhance crashworthiness.

- Corrosion resistance: Unlike metal, composite materials are not susceptible to rust and corrosion. This means that 3D-printed school buses can maintain their structural integrity and safety features over a longer period of time, even in harsh weather conditions.

The enhanced safety of 3D-printed school buses is a major advantage over traditional buses. By using advanced materials, 3D printing can create buses that are more durable, crashworthy, and corrosion-resistant, providing a safer transportation environment for students.

4. Environmental sustainability

The environmental sustainability of 3D-printed school buses is a key advantage over traditional buses. Traditional buses rely on fossil fuels, which contribute to greenhouse gas emissions and air pollution. In contrast, 3D-printed buses can be manufactured using sustainable materials and powered by electric motors, significantly reducing their environmental impact.

- Sustainable materials: 3D-printed buses can be made from a variety of sustainable materials, such as recycled plastics, plant-based materials, and lightweight composites. These materials are not only environmentally friendly but also offer advantages such as durability and corrosion resistance.

- Electric motors: Electric motors are more efficient and environmentally friendly than combustion engines. 3D-printed buses can be powered by electric motors, eliminating tailpipe emissions and reducing noise pollution.

- Reduced carbon footprint: By using sustainable materials and electric motors, 3D-printed buses can significantly reduce their carbon footprint compared to traditional buses. This contributes to cleaner air and a healthier environment for students and communities.

The environmental sustainability of 3D-printed school buses is an important factor for schools and transportation providers to consider. By choosing 3D-printed buses, schools can demonstrate their commitment to environmental responsibility and provide students with a greener mode of transportation.

FAQs on School Bus 3D Printing

This section addresses common questions and concerns regarding the use of 3D printing technology in the production of school buses.

Question 1: Are 3D-printed school buses safe?

Answer: Yes, 3D-printed school buses are designed and manufactured to meet or exceed safety standards. They are constructed using advanced materials that provide enhanced durability, crashworthiness, and corrosion resistance, ensuring the safety of students.

Question 2: Are 3D-printed school buses expensive?

Answer: While the cost of 3D printing technology is still evolving, advancements in the field have led to significant cost reductions. 3D-printed school buses offer a cost-effective alternative to traditional buses, especially when considering their durability and longevity.

Question 3: Are 3D-printed school buses environmentally friendly?

Answer: Yes, 3D-printed school buses are more environmentally friendly than traditional buses. They can be manufactured using sustainable materials and powered by electric motors, reducing their carbon footprint and contributing to cleaner air and a healthier environment.

Question 4: Are 3D-printed school buses customizable?

Answer: Yes, 3D printing offers greater design flexibility compared to traditional manufacturing methods. Schools can customize the design of their buses to meet specific needs and preferences, including seating arrangements, accessibility features, and exterior designs.

Question 5: Are 3D-printed school buses widely available?

Answer: The adoption of 3D-printed school buses is growing, but it may vary depending on the region and availability of 3D printing facilities. However, as the technology continues to advance and costs decrease, 3D-printed school buses are expected to become more widely available in the future.

Question 6: What are the potential long-term benefits of 3D-printed school buses?

Answer: 3D-printed school buses have the potential to transform student transportation in the long term. They offer cost savings, design flexibility, enhanced safety, and environmental sustainability, making them a promising solution for schools and transportation providers.

In summary, 3D-printed school buses offer a range of advantages over traditional buses, addressing concerns related to safety, cost, environmental impact, customization, availability, and long-term benefits. As the technology continues to mature and gain wider acceptance, 3D-printed school buses are poised to play a significant role in improving student transportation.

Transition to the next article section:

For more information on the technical aspects of 3D printing and its applications in the transportation industry, please refer to the following resources:

- Resource 1

- Resource 2

- Resource 3

Tips on School Bus 3D Printing

The adoption of 3D printing technology in school bus manufacturing offers numerous advantages. To maximize these benefits, consider the following tips:

Tip 1: Research and identify reputable 3D printing providers.

Thoroughly research and evaluate 3D printing companies to ensure they have the expertise, experience, and capacity to deliver high-quality school buses that meet safety and performance standards.

Tip 2: Collaborate with design professionals to optimize bus design.

Engage with experienced designers to create customized bus designs that align with your specific requirements, considering factors such as seating arrangements, accessibility features, and exterior aesthetics.

Tip 3: Select durable and sustainable materials.

Choose 3D printing materials that are durable, corrosion-resistant, and environmentally friendly. This ensures the longevity and sustainability of your school buses.

Tip 4: Implement quality control measures.

Establish rigorous quality control processes throughout the 3D printing and assembly stages to guarantee the safety and reliability of your school buses.

Tip 5: Consider electric motors for sustainable transportation.

Opt for electric motors to power your 3D-printed school buses, reducing emissions and promoting environmental sustainability.

Tip 6: Explore funding opportunities and partnerships.

Investigate government grants, partnerships with local businesses, and other funding opportunities to support the adoption of 3D-printed school buses.

Tip 7: Educate stakeholders and promote awareness.

Engage with school administrators, parents, and community members to educate them about the benefits of 3D-printed school buses, addressing any concerns and fostering support.

Tip 8: Monitor advancements and best practices.

Stay abreast of the latest advancements in 3D printing technology and best practices in school bus manufacturing to continually improve the safety, efficiency, and sustainability of your fleet.

By following these tips, schools and transportation providers can harness the full potential of 3D printing technology to transform student transportation, enhance safety, and create a more sustainable future.

Transition to the article’s conclusion:

In summary, 3D printing offers a groundbreaking approach to school bus manufacturing, providing numerous advantages over traditional methods. By embracing these tips, stakeholders can effectively implement 3D-printed school buses, revolutionizing student transportation and creating a safer, more sustainable, and innovative learning environment.

Conclusion

The exploration of “school bus 3D print” has unveiled the transformative potential of 3D printing technology in the realm of student transportation. This innovative approach offers a multitude of advantages, including cost-effectiveness, design flexibility, enhanced safety, and environmental sustainability. By embracing 3D printing, schools and transportation providers can create customized buses tailored to their specific needs, ensuring the well-being and comfort of students.

As 3D printing technology continues to advance, the future of school transportation looks brighter than ever. The adoption of 3D-printed school buses can pave the way for safer, more sustainable, and more efficient student transportation systems. By investing in this technology, we can create a future where every child has access to a safe and reliable ride to and from school.